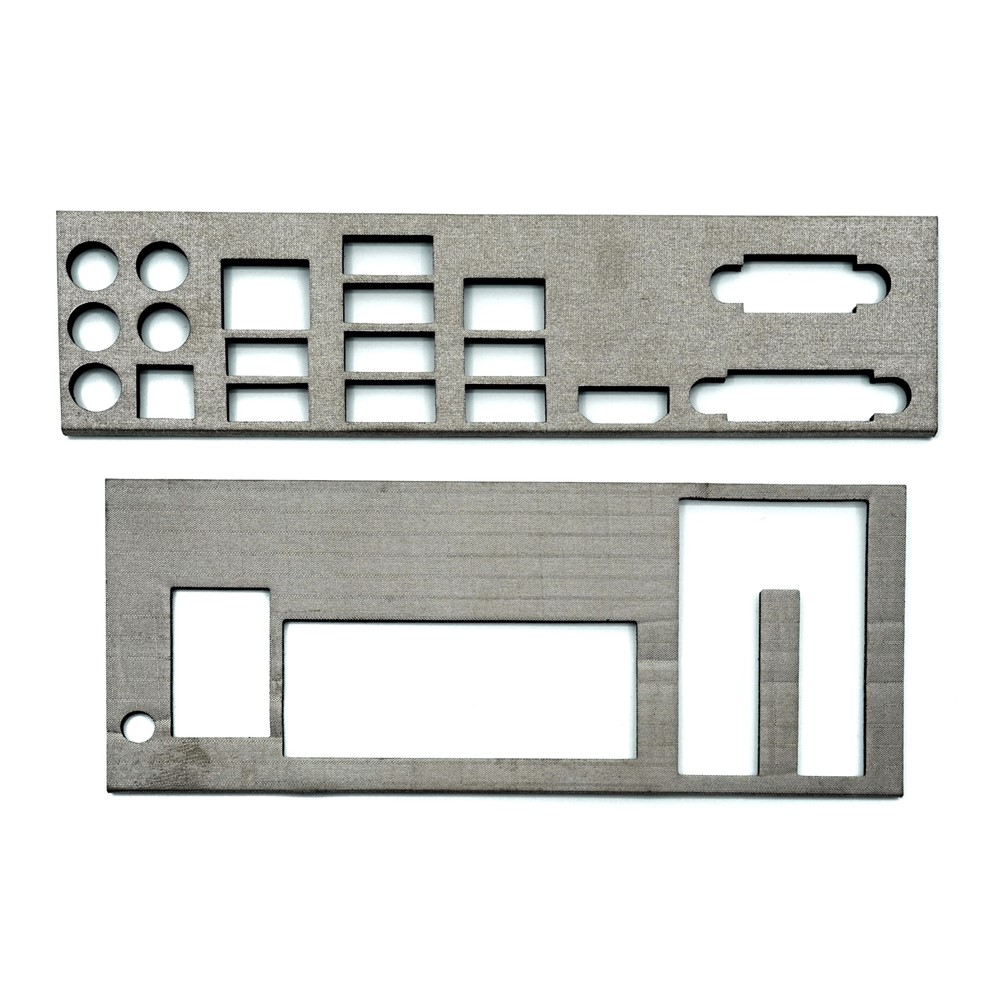

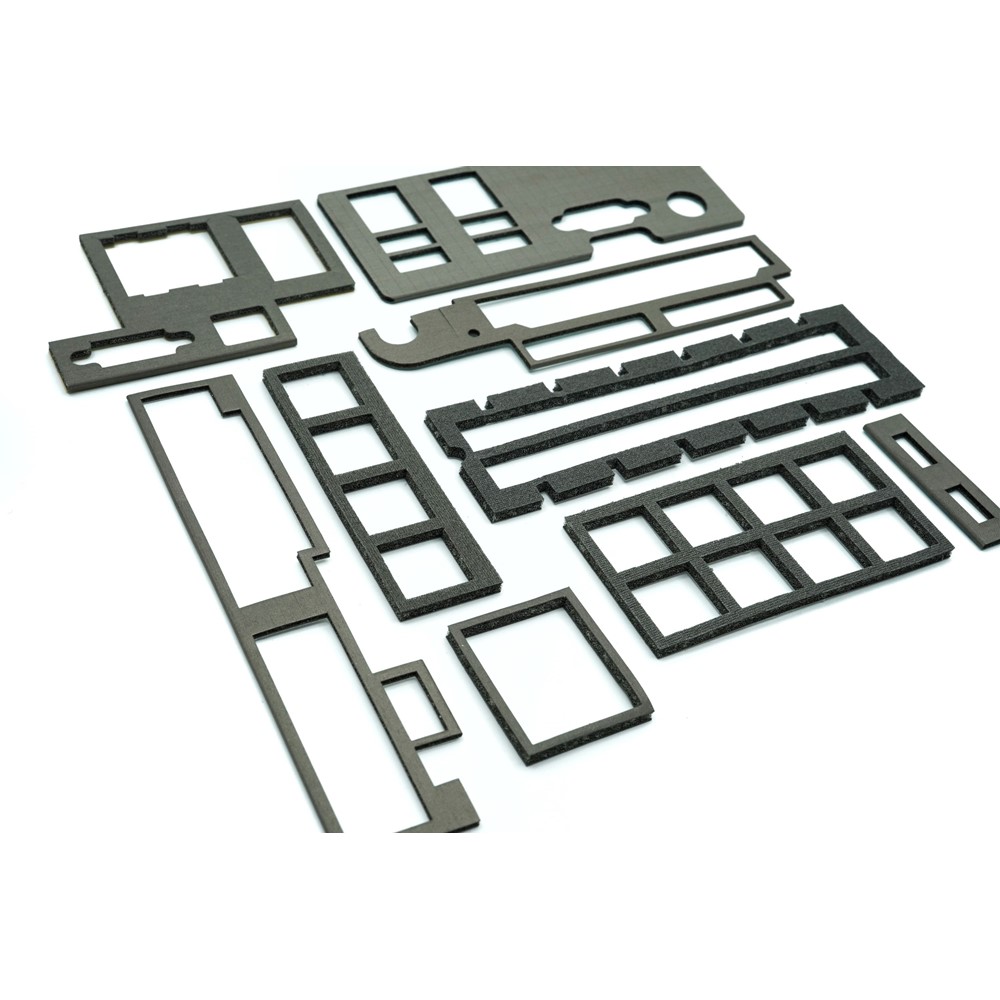

Precision Die-cuts

Die-cutting is the process of cutting material into various shapes & sizes. Glocom can die-cut a wide variety of non-metallic or flexible materials like rubbers, foams & adhesives. We select the right tool using our experience and offer inexpensive tooling options like soft/ steel rule dies. For non-profiled parts, we are equipped with XY Super-Cutter to perform dieless knife cutting.

Using the best machines & equipment available, our production lines are well equipped to process high complexity products and provide high volumes of output.

We supply high quality parts for various applications which include multiple layers of lamination processes to meet customer’s requirement.

Materials we work with for die cuts / kiss-cuts:

- Almost all types of Foams and rubbers

- Conductive and ESD sensitive materials

- Felted sheets (Synthetic & Natural Wool)

- Adhesive, protective PET/Acrylic lamination of continuous sheets.

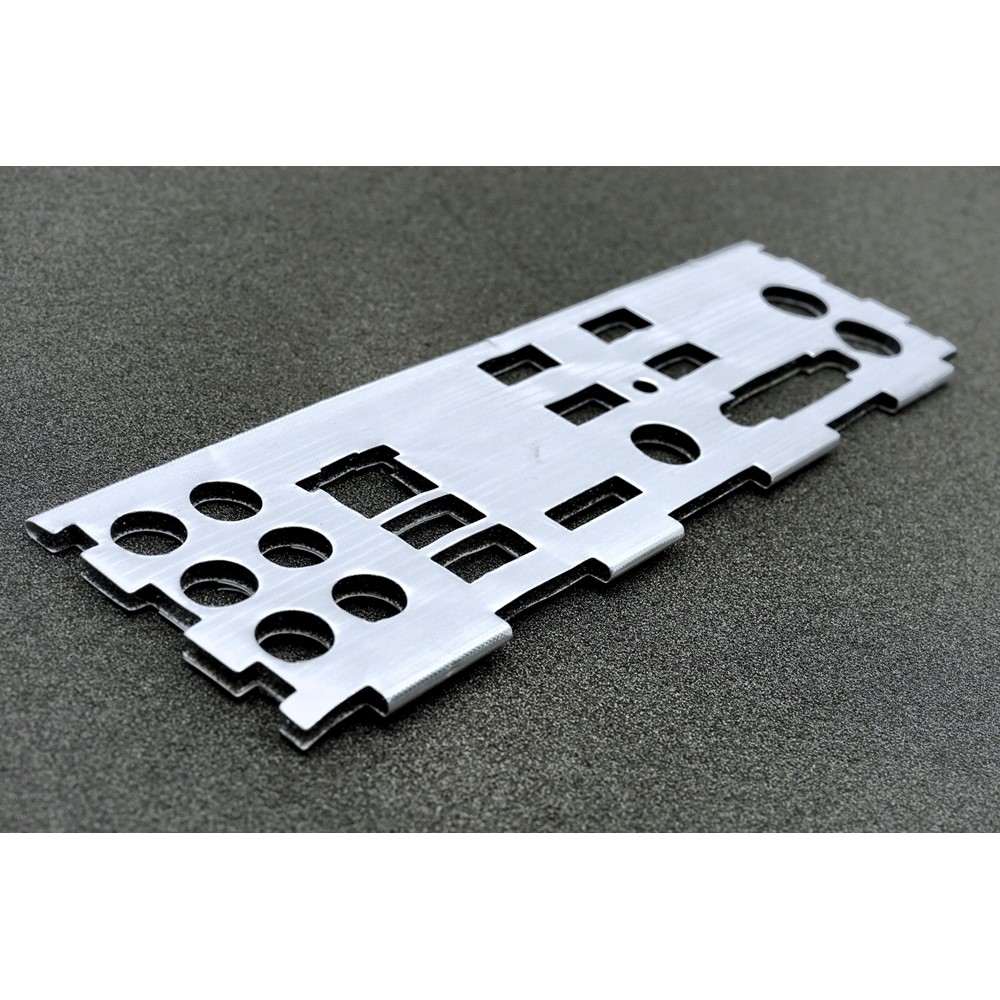

Die-Cut Machines

8 machines in production

- 1 XY cutting machine

- 1 desktop die cut machine

- 1 straight cut die cut machine

- 5 automatic high speed precision die cut machines

- In house developed 100% auto inspection machine

Machine Capabilities

- Fully computerized control

- Choices of different cutting tools E.g, Pinnacle, Steel rule die

- Low cost & short tool fabrication time

- Low set up cost

- Multi cavities die cutting

- Quick turnaround time due to easy setup

- Wide range of die cut substrate Eg. PC, PET, PE, Silver Foil, Poron etc.

- Recommended application eg. insulation, pad etc

- In house developed 100% auto inspection machine

- Max. die cut area 500mm x 500mm

- Wide range of raw material – 0.5mm to 1mm

- Relatively good dimensional accuracy

- Hard tool for precision better dimensional accuracy and control

- Recommended for high volume parts

- Longer tool life

- Surface tension treatment machine.

- In house developed 100% auto inspection machine

- Controlled clean environment