Glocom leverages the experience of strong technical teams from each focus factory to design solutions to your interference problems. Engineering disciplines include: *Microwave* Radar, EMI/ EMC *Polymer Science* Production Processes.

Our experience and capabilities in the area of compression moulded elastomers and our in-house rubber milling operation make us the only fully integrated MAGRAM manufacturer in the US. Glocom Syntactic Foam products, consisting of both tailored dielectric and controlled loss versions, have gained widespread acceptance for use in aircraft, space and antenna applications.

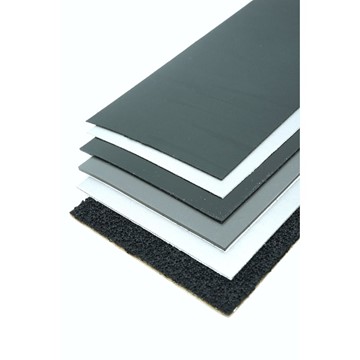

FOAM

Lossy Flexible Foam

The LS product is a flexible, low density, high loss, carbon impregnated open cell foam. It is available in a range of thicknesses with various carbon loading. The carbon loading allows it to be effective over a broad range of frequencies, typically providing 5 dB loss or greater. This product is halogen free, RoHS and REACH compliant.

Product Overview

The LS series is an open cell foam with carbon loading. It is available in sheet form, has low density, is light weight and can be custom carbon loaded to meet high or low loss requirements. It is effective for far field requirements. This product is typically used in a multi-layer form taking advantage of the layering of various carbon loadings. LS foam is ideal for suppression of electromagnetic energy. Placement in a cavity will reduce multiple reflections, which result in improved performance. Product provides broadband absorption from 500MHz to 40GHz.

Why LS is effective

The LS material is effective due to its open cell foam construction with its ability to retain various carbon loadings to absorb the EMI. The open cell foam can be for outdoor applications. The absorbers can be weather sealed for outdoor protection.

When to Use

- Crosstalk reduction

- Antenna shrouding

- Shadowing parts for RCS Measurements

- Shadowing components of anechoic chambers

- Typically used in multi-layer format

- Broad band absorption

- Elastomer coatings can be added to resistance against:

- Jet fuel

- Hydrolic fuel

- Gasoline

- Water

Reticulated Foam

The RT series is a group of open-cell, carbon-loaded foam absorbers. Exacting control of the conductive gradient provides outstanding broadband performance. RT’s open cell structure is an excellent conduit for convective airflow. Lightweight and flexible, RT is offered in flat form or in a convoluted format for higher electrical performance. This product is halogen free, RoHS and REACH compliant.

Product Overview

- Broadband absorption from 500 MHz to 40 GHz

- Flexible and lightweight

- Permits convective airflow

- Easily cuts to shape

- Conductive ground plane available

- Easy attachment with pressure sensitive adhesive

- Flat or convoluted formats

- Surface treatment available for outdoor or harsh environment applications

Why RT is effective

Similar to the LS and ML series foams, the large open cells of the foam along with Glocom exacting control of applying the conductive gradient allows Glocom to target specific frequencies.

When to use

- Minimize reflections in enclosures.

- Suppress reflections across a wide frequency spectrum

MAGRAM

MagRAM DD

MagRAM DD combines superior energy absorption properties of high performance magnetic materials with the desirable physical properties of silicone. The result is a thin, flexible resonant absorber that can be specifically tuned to narrow or broadband depending on filler selection.

Product Overview

MagRAM DD is a flexible, loaded silicone rubber based microwave absorber that can be tuned for narrowband mode suppression in an enclosed cavity, signal isolation and surface current attenuation. Mechanically stable, and resistant to extreme environments and temperatures, it has good tensile strength, elongation, tear strength and compression set that is far superior compared against conventional rubbers. This product is halogen free, RoHS and REACH compliant. Attenuates from 500 MHz to 40GHz

Why MAGRAM DD is effective

Silicone rubber is a highly inert material and does not react with most chemicals. The selection of fillers makes it effective as an absorptive material.

When to use

MAGRAM DD is most effectively used where the silicon material properties can be taken advantage of, especially when environmental resilient is required. With any of the MAGRAM series the fillers can be combined with various binders.

- Specular Return (RCS, aircraft exteriors)

- Surface Current Reduction

- System Isolation (antenna, circuit component)

- High Temperature Resistance

- UL94-VO is Required

MagRAM UD

MagRAM UD combines superior energy absorption properties of high performance magnetic materials with the desirable physical properties of urethane. The flexible, loaded urethane rubber based microwave absorber can be tuned for mode suppression in an enclosed cavity, signal isolation and surface current attenuation.

Product Overview

MAGRAM UD is mechanically stable, and resistant to extreme environmental effects and temperatures, it has good tensile strength, elongation, tear strength and compression set that can be far superior to conventional rubbers. This product is halogen free, RoHS and REACH compliant. Attenuates from 500 MHz to 40GHz

Why MAGRAM UD is effective

The urethane binder is typically utilised in a high abrasion environment taking advantage of its superior tear strength and UL 94-HB rating. This binder in combination with the various fillers makes it effective for absorption.

When to use

MAGRAM UD is most effectively used where the urethane material properties can be taken advantage of, especially when environmental resilient is required. With any of the MAGRAM series the fillers can be combined with various binders.

MagRAM FD

MagRAM FD series combines superior energy absorption properties of high performance magnetic materials with the desirable physical properties of Viton (Fluroelastomer). FD series Viton (Fluroelastomer) rubber based microwave absorber can be tuned for mode suppression in an enclosed cavity, signal isolation and surface current attenuation.

Product Overview

Magram FD series contains a flexible Viton (Fluoroelastomer) binder known for its excellent (400°F/200°C) heat resistance in addition to having excellent resistance to aggressive fuels and chemicals. Viton (Fluroelastomer) MagRAM is especially suited for use when the product is in the presence of high temperatures or has potential exposure to a corrosive environment or fuel/chemical splash.

Why MAGRAM FD is effective

MAGRAM FD series contains a flexible Viton (Fluroelastomer) rubber binder. It is a microwave absorber tuned for mode suppression in an enclosed cavity, signal isolation and surface current attenuation. MagRAM FD is mechanically stable and extremely resistant to chemicals. It is also resistant to moisture, fluids and most fuels. Viton (Fluroelastomer) exhibits good chemical stability, and performs in a wide temperature range. Attenuates from 500MHz to 40GHz

When to use

FD series Viton (Fluorocarbon) exhibits resistance to a broader range of chemicals combined with very good high temperature properties more so than any of the other elastomer. MAGRAM FD is also resistant to swelling when exposed to gasoline as well as degradation due to exposal to UV light and ozone.

MagRAM ND

MagRAM ND combines superior energy absorption properties of high performance magnetic materials with the desirable physical properties of nitrile. The ND nitrile rubber based microwave absorber can be tuned for mode suppression in an enclosed cavity, signal isolation and surface current attenuation.

Product Overview

MagRAM ND is a flexible nitrile rubber. It is a microwave absorber tuned for mode suppression in an enclosed cavity, signal isolation and surface current attenuation. Mechanically stable, and resistant to extreme environments and temperatures, it is resistant to moisture, fluids and fuels. This product is halogen free, RoHS and REACH compliant. Attenuates from 500 MHz to 40GHz

Why MagRAM ND is effective

Nitrile rubber is a highly inert material and does not react with most chemicals. The nitrile material is effective in a high moisture environment. It also resists exposure to fluids and fuel.

When to use

MagRAM ND is most effectively used where the nitrile material properties can be taken advantage of, especially when environmental resilient is required. It is effective in aeronautical applications for example, due to its ability to resist oil, fuel, and high moisture. MagRAM ND also has the ability to withstand a range of temperatures from -40°C to +149°C and is UL94-HB rated.

MagRAM CD

MagRAM CD Series combines superior energy absorption properties of high performance magnetic materials with the desirable physical properties of Neoprene. CD Series Neoprene rubber based microwave absorber can be tuned for mode suppression in an enclosed cavity, signal isolation and surface current attenuation.

Product Overview

MagRAM CD Series contains a flexible Neoprene rubber binder. It is a microwave absorber tuned for mode suppression in an enclosed cavity, signal isolation and surface current attenuation. Mechanically stable, and resistant to extreme environments and temperatures, it is resistant to moisture, fluids and some fuels. Neoprene exhibits good chemical stability, and maintains flexibility over a wide temperature range. This product is halogen free, RoHS and REACH compliant. Attenuates from 500MHz to 40GHz

Why MAGRAM CD is effective

Neoprene rubber has excellent weathering resistance properties. CD Series Neoprene MagRAM material is effective in a high moisture environment and maintains excellent performance when exposed to outside elements.

When to use

MagRAM CD Series Neoprene resists degradation from sun, ozone and weather while performing well when in contact with oils and some chemicals. Neoprene maintains its strength, flexing, and elongation very well over a wide temperature range while having outstanding physical toughness.

HONEYCOMB ABSORBER

A lightweight core material that is constructed with hexagonal cells. It can be tuned to operate at various frequencies over a broad spectrum. The electrical performance can be maximized for insertion/transmission or reflection loss. Honeycomb absorbers are fabricated from a range of materials including phenolic, high-temperature aramid & fiberglass.

Product Overview

- Designed to enhance antenna performance

- Ultra lightweight yet mechanically durable

- Superior electrical performance

- Machined to complex 3D configurations

Why Honeycomb is effective?

With our proprietary lossy formulation and loading technique we can tailor honeycomb to offer maximized performance from low to high frequencies. With the construction, configuration and cell structure it offers outstanding reflection, insertion/ transmission loss.

When to use?

- When structural integrity is critical

- Material weight is a concern

- High power handling applications

- Convective cooling is required

- Broadband performance

- Frequency Range: 500MHz to 40GHz

- Temperature Range: -70F to +350F (-56C to +177C)

- Size Range: Can be machined to complex custom configurations or in sheet form per cus-tomer specifications.

- Also available in various cell sizes (.187″ and .250″ are most common).

Applications

- Antenna Cavity Inserts

- Enhance Antenna Performance

- RAS (Radar Absorbing Structure)

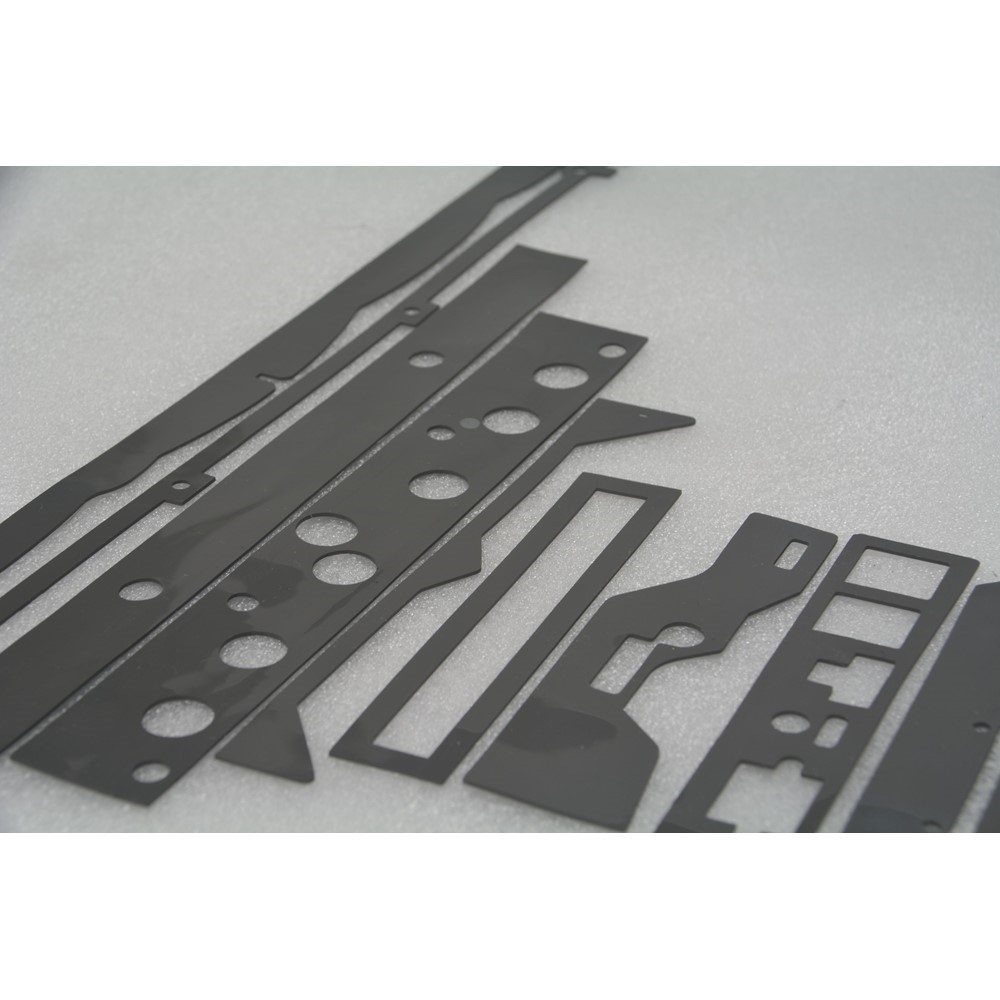

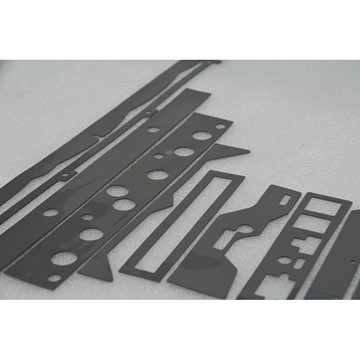

THERMOPLASTICS

Glocom blends thermoplastics with fillers to create customized solutions. Glocom can manufacture thermoplastics to be used in a cast, molded, extruded, or pellet form. In the binder Glocom can compound different fillers (typically: carbon, ferrite or iron particles) to achieve the desired absorption or conductivity to solve the problem.

By combining a binder into a form that meets the product requirements and with the proper electrical and/or magnetic conductive fillers, a complete solution can be found for every situation.

Why Thermoplastics are effective?

Thermoplastics, due to its’ moldable properties, is a very versatile tool for product designers. Parts can be molded to snap over the IC’s, or extruded to wrap and cover a product or cable, or sold as pellets so the end customercanmold/extrude their own product. The use of fillers allows Glocom to tune the end product for narrow or broadband applications. This product line is very flexible and versatile. Glocom can mold components for you, or extrude sheet and apply PSA (pressure sensitive adhesives) to it, or supply it in pellet form to an external molder.

|

|